製品カテゴリ別に探す

Search by product category

|

|

価格はお問い合せください 価格はお問い合せください |

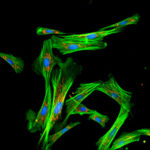

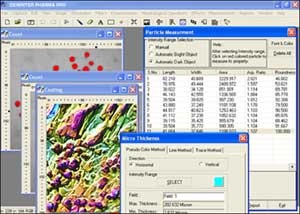

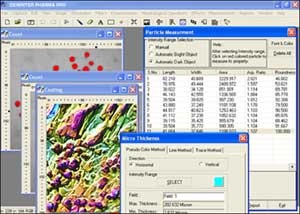

The use of microscopic image analysis system is the most reliable technique to characterize particle shape and to characterize a particle size and volume distribution. Tradition method, such as laser diffraction, although efficient, gives limited information on particle shape. The particle size, distribution and shape of the particles can effect bulk properties, product performance, process ability, stability and appearance of the end product in Pharma industry.

The software is useful to measure and analyse the particle size, particles shape, particle count, foreign particle detection, particle structure, homogeneity, surface coatings thickness. For spherical particles (which are rarely uncounted in pharmaceutical powders) the diameters are sufficient to describe the particle size. For non-spherical particles, feret’s diameter, Particle orientation, Particle shape, elongation, convexity, circularity, circle equivalent diameter are measured.

This software is also useful to study the polarizing effects which study the cross section through pharmaceutical tablets by preparing thin-sections on slide with UV curing adhesive for final polishing. The cross section reveal the spatial distribution of components in the tablets so that any post compression change (eg polymorph conversions or change in the hydration state of components) can be investigated.

製品カテゴリ別に探す

Search by product category

|

|

価格はお問い合せください 価格はお問い合せください |

This software is powerful for acquiring, organizing, storing, retrieving and editing any image. It handles different image formats BMP, TIFF, IMG, IMF, GIF, PCX, JPEG, PIC. It support many cameras, frame grabbers and other USB-1, USB-2 & twain input devices. The Software provide user friendly platforms to measure length, width, height, thickness, perimeter, radius, angle, area etc on an object captured from any source. Creates customized reports with images, data & text.

製品カテゴリ別に探す

Search by product category

|

|

|

価格はお問い合せください 価格はお問い合せください |

Microhardness testing applied in areas including metallography, precision mechanics, electroplating, material testing and material science. In order to determine microhardness, different shaped indents are pressed into flat material samples with a defined force. Three methods available are :

BRINELL HARDNESS

In Brinell hardness test, an indentation hardness test in which a hardmetal ball is forced into the surface of a test piece, mean diameter of the indentation is left on the surface after removal of the test force is measured.

The Brinell hardness HBW is obtained by software.

VICKERS HARDNESS

The Vickers hardness test, measure length of the diagonals of indentation left in the surface in which a Square-based diamond pyramid, having an angle of 136 degree between the opposite faces at the vertex, is forced. The Vickers hardness is obtained by dividing the test force by the area of the sloping faces of the indentation. The Vickers hardness HV is displayed by software.

KNOOP HARDNESS

The Knoop hardness test is an indentation hardness test in which a rhombic-based diamond pyramid, having an included longitudinal edge angle of 172.5 degree and an included transverse edge angle of 130 degree, is forced into the surface of a test piece. The length of the long diagonal of the indentation left in the surface after removal of the test force. The Knoop hardness HK is calculated by software.

製品カテゴリ別に探す

Search by product category

|

|

価格はお問い合せください 価格はお問い合せください |

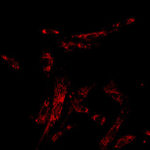

Weld Check software is a powerful easy-to-use tool that enhances your ability to quickly and efficiently handle your most critical welding measurement and documentation software needs. Your workflow and productivity are greatly improved. Weld Check has been designed with your welding cross-section measurement needs in mind. Weld Check’s measurement module allows you to quickly measure such items as your fillet welds, throat, leg lengths and penetration.

Use Weld Check Measurement Tolerance indicator to improve performance by having the software automatically tell you if a measurement is out of the tolerance range.

The following report concerns the analysis of a fillet weld, a weld of approximately triangular cross section joining two surfaces at approximately right angles to each other. Important measurements made by the distance from the root if the fillet to the center of the face (or throat), the distance from the root of the joint to the junction between the exposed surface of the weld and the base metal (or leg), the angles and the root penetration.Measurements that could have been done with the same ease or similar sample are among others : depth of HAZ (heat affected zone), area of HAZ, joint penetration, phase counting, etc.

The measurement remain uneffected if the image is zoomed for better accuracy. T he magnifier tool is also available which can be switched on any part of image. The tool zooms only the region surrounding the cursor allowing to increase the drawing precision while still seeing the whole sample.

Image analysis system can measure a sequence of specific characteristics or welded parts. The system brings the good tool with the good color when it’s the time for the operator to use it.

製品カテゴリ別に探す

Search by product category

|

|

| 価格はお問い合せください |

Material Plus 4.1 is a comprehensive solution of all Micro graphic methods used to test metal and their products. The wizard (modules) available are confirming all equivalent national & international methods. The available wizards are :

GRAIN SIZE

ASTM E-112, E-930, E-1181, ISO 643-03, JIS G 0551-05 BS 490 DIN 643-03, IS-4748-88, SIS 111101 GOST 5639-82.Determine feritic and austenitic Grain Size in Steel. The available methods are :

1. Automatic & Semi automatic Lineal Heyn Intercept method. 2. Jeffries Planimetric Method. 3. Automatic and Semiautomatic Snyder and Graff Open Scale Intercept Method. 4. Comparison Method. 5. ALA Grain Size. 6. Selected Grain Size 7. Manual Count etc.

GRAPHITE FLAKES

ASTM A247, ISO 9451-1, DIN EN 945-94, BIS 7754 JIS G5504, IS-7754. Flakes occuring in Cast Iron are designated by Form (by Roman no. I to VI) Distribution (designated by capital letter A to E) and Size (designated by Arabic no 1 to 8).

CASE DEPTH

ASTM ISO 2639-02, BS-6479-84, IS-6416-88 JIS G0557 DIN 50790. The test determine the depth of hardened surface under low magnification by measuring the distance from the surface to the point shaving a different coloration towards core.

POROSITY ASTM 247

Pores in casting are estimated and reported on the basis of intensity. The percentage is calculated.

NON-METALLIC INCLUSION

ASTM E-1245 E ASTM E45-97, ISO 4163-82, DIN 50602. The wizard determine contents of Non-metallic. Inclusion in rolled or forged steel products. According to ASTM, expression of results are in Group A, B, C, D along with segmentation of thick/thin and its severity level.

NODULARITY

ASTM A 247-67, ISO-9451-1, IS-7754 DIN E 945-94, JIS G5504, BIS 7754 JIS G5504. Nodules (spheroidal Graphite in Cast Iron) are separated from Non Nodules on predefined spheroidicity. Nodules/Sqmm are calculate and on the basis of its size and it is designed by Arabic no. 1 to 8 according to ASTM & ISO standards.

DECARBURIZATION

ASTM E1077, ISO 3887, JIS-0557-98 BS-6617-1, IS-7754 DIN 50192. The depth of decarburization in unalloyed and low alloy steel is determined by Micro graphic Method. Depth of Partial, total and complete decarburization is reported separately.

製品カテゴリ別に探す

Search by product category

顕微鏡加熱ステージは観察試料を加熱するときに用いる試料台で、顕微鏡用ヒートステージ、顕微鏡用ホットステージとも呼ばれます。正立/倒立生物顕微鏡用、偏光顕微鏡用などがあります。温度範囲には室温~70℃、室温~450℃などがあり、-40℃まで冷却できるタイプもございます。

| 顕微鏡加熱ステージ |

| 型番 |

用途・温度範囲 |

外観 |

| KEL-2000 |

正立生物顕微鏡用 |

室温~70℃ |

|

| KEL-2000A |

倒立生物顕微鏡用 |

室温~70℃ |

|

| KEL3100-08S |

偏光顕微鏡用 |

室温~450℃ |

|

| KEL51008SF |

生物/金属/偏光/実体顕微鏡用 (冷却加熱ステージ) |

-40~50℃ |

|

| KEL-X-4 |

融点試験用 |

室温~250℃ |

|

| メーカ |

NANJING KOZO OPTICAl AND ELECTRONICAL INSTRUMENT CO., LTD |

製品カテゴリ別に探す

Search by product category

ファイバ照明はハロゲンランプの光をファイバガイド(バンドルファイバ)でフレキシブルに導く顕微鏡用照明です。ガイド1本タイプ、ガイド2本タイプ、リングタイプの3種類があります。価格はお問い合せください。

| ファイバガイド |

| ガイドタイプ |

型番 |

剛性 |

外径 (mm) |

長さ(m) |

写真 |

| リングガイド |

RG-S-8-1 |

柔軟 |

Φ8 |

1 |

|

| ダブルガイド |

WG-H-8-0.6 |

堅い |

Φ8 |

0.6 |

|

| WG-H-6-0.6 |

Φ6 |

0.6 |

| WG-S-8–0.6 |

柔軟 |

Φ8 |

0.6 |

| WG-S-6-0.6 |

Φ6 |

0.6 |

| シングルガイド |

SG-H-8-0.6 |

堅い |

Φ8 |

0.6 |

|

| SG-H-6-0.6 |

Φ6 |

0.6 |

| SG-S-8-0.6 |

柔軟 |

Φ8 |

0.6 |

| SG-S-6-0.6 |

Φ6 |

0.6 |

| ハロゲンランプ |

| パラメータ |

値 |

写真 |

| 入力電圧 |

AC115V/AC230V±15%, 50*60Hz, 150W |

|

| 出力電圧 |

DC3V~DC21V±10%,, ランプ電流7A(Max.) |

| フューズ |

T4AL250V |

| 電気耐性 |

1750VAC/5MA/1分以内のブレークダウンなし |

| ランプ |

21V 150W ハロゲンランプ |

| ランプ寿命 |

200H以上 |

| 演色評価数 |

85 |

| 色温度 |

2500K – 3200K (フィルタなし) |

| 5600K Max. (フィルタあり) |

| 照度 |

>120000 LX |

| 冷却 |

空冷 |

| 動作温度 |

-20℃ ~ 45℃ |

| 保管温度 |

-10℃ ~ 60℃ |

| 動作湿度 |

80% RH (31℃) |

| 50% RH 40℃) |

| 使用高度 |

2000m Max. |

| 使用環境 |

導電性塵埃、腐食性ガスのない環境 |

| メーカ |

NANJING KOZO OPTICAl AND ELECTRONICAL INSTRUMENT CO., LTD |

製品カテゴリ別に探す

Search by product category

| 型番 |

仕様 |

外観 |

| LEDリング照明 |

| LED 48 |

LED数 |

48 |

|

| 電源 |

100~240V |

| 消費電力 |

5W |

| 明るさ |

可変 |

| 内径 |

62mm |

| LED 72 |

LED数 |

72 |

| 電源 |

100~240V |

| 消費電力 |

5W |

| 明るさ |

可変 |

| 内径 |

62mm |

| メーカ |

NANJING KOZO OPTICAl AND ELECTRONICAL INSTRUMENT CO., LTD |

製品カテゴリ別に探す

Search by product category

|

| 3眼鏡筒用(タイプ C)

|

| 型番 |

TCD140 |

TCD330 |

TCD500 |

TCD600 |

TCD140C |

TCD140H |

| CCD サイズ |

1/2 インチ |

1/1.8 インチ |

2/3 インチ |

1.8 インチ |

2/3 インチ |

2/3 インチ |

| センサーフォーマット |

プログレス |

インターライン |

インターライン |

インターライン |

プログレス |

プログレス |

| センサータイプ |

ソニー ICX205AK |

ソニー ICX412AQ |

ソニー ICX282AQ |

ソニー ICX413AQ |

ソニー ICX285AQ |

ソニー ICX285Al |

| ピクセルサイズ |

4.65*4.65μm |

3.46 *3.46μm |

3.4 *3.4μm |

7.8 *7.8μm |

6.45 *6.45μm |

6.45*6.45μm |

| G センシティビティー |

400mV |

455mV |

280mV |

455mV |

1200mV |

1200mV |

| 分解能 |

1360H*1024V |

2048H*1536V |

2580H*1944V |

3032H*2016V |

1360H*1024V |

1360H*1024V |

| フィルタ |

R, G, B |

R, G, B |

R, G, B |

R, G, B |

R, G, B |

R, G, B |

| 最大フレーム

レイト |

12.5fps |

5fps |

3fps |

2.9fps |

12.5fps |

12.5fps |

| (1360*1024) |

(2048*101536) |

(2580*1944) |

(3032*2016) |

(1360*1024) |

(1360*1024) |

| 15fps |

30fps |

10fps |

10fps |

15fps |

15fps |

| (680*520) |

(680*520) |

(1280*932) |

(720*400) |

(680*520) |

(680*520) |

| ファン |

30*30/5000rpm |

30*30/5000rpm |

30*30/5000rpm |

30*30/5000rpm |

30*30/5000rpm |

70*70/5000rpm |

| 電源 |

3.5V |

3.5V |

3.5V |

3.5V |

3.5V |

12V |

| 露光制御 |

自動 / 手動 |

| プログラム制御 |

イメージサイズ,露光時間, 明るさ, ゲイン, ガンマ補正, 色, コントラスト, サチュレーション |

| 出力データ |

RGB24, DirectShow, Twain インターフェース |

| 露光時間 |

1/1000秒-60分 |

| ホワイトバランス |

自動 / 手動 |

| USB電源 |

USB 2.0 |

| 高/低速読み出し |

Yes |

| 動作温度 |

-30℃~60℃ |

| ソフトウエア |

ドライバ: support DirectShow and Twain |

| イメージソフトウエア: MiniSee |

| 画像処理ソフト: ScopePhoto (オプション) |

| 動作環境 |

Windows 2000 / Me / XP(SP2/SP3) / 2003 / Vista / 2008 32Bit system |

| 適合規格 |

CE |

| ペルチェ冷却 |

周囲温度より-30℃ 以下にペルチェ冷却 |

| メーカ |

NANJING KOZO OPTICAl AND ELECTRONICAL INSTRUMENT CO., LTD |

製品カテゴリ別に探す

Search by product category

| 型番 |

TCCISH130 |

TCCISH300 |

TCCISH500 |

TCCISH1000 |

| センサ |

Micron MT9M111 |

Micron MT9T001 |

Micron MT9P031 |

Micron MT9J001 |

| センササイズ |

1/3 インチ |

1/2 インチ |

1/2.5 インチ |

1/2.3 インチ |

| ピクセルサイズ(μm) |

3.6 x 3.6 |

3.2 x 3.2 |

2.2 x 2.2 |

1.67 x 1.67 |

| カラー/モノクロ |

カラー |

カラー |

カラー |

カラー |

| 有効画素数 |

1.3 MP |

3.0 MP |

5.0 MP |

10.0 MP |

| 最大解像度 |

1280 x 1024 |

2048 x 1536 |

2592 x 1944 |

3664 x 2748 |

| スキャンモード |

プログレッシブ |

プログレッシブ |

プログレッシブ |

プログレッシブ |

| シャッター |

ローリング |

ローリング |

ローリング |

ローリング |

| インタフェース |

USB 2.0 |

USB 2.0 |

USB 2.0 |

USB 2.0 |

| フレームレート |

15fps(1280 x 1024) |

10fps(2040 x 1528) |

5fps(2584 x 1936) |

3fps(3656 x 2732) |

| 33fps(1015 x 760) |

21fps(1272 x 952) |

8fps(1824 x 1362) |

| 46fps(632 x 472) |

38fps(632 x 472) |

28fps(908 x 672) |

| 色深度 |

|

24 bit |

24 bit |

24 bit |

| A/D |

8 bit / 10 bit |

8 bit |

8 bit |

8 bit |

| 露出制御 |

マニュアル/オート |

マニュアル/オート |

マニュアル/オート |

マニュアル/オート |

| 積算時間 |

1ms~0.5s |

1ms~1.2s |

1ms~1.5s |

1ms~1.2s |

| ホワイトバランス |

マニュアル/オート |

マニュアル/オート |

マニュアル/オート |

マニュアル/オート |

| 応答性 |

2.1V/lux-sec |

>1.0V/lux-sec |

1.4V/lux-sec |

0.34V/lux-sec |

| ダイナミックレンジ |

68.2dB |

61dB |

70.1dB |

66.5dB |

| SNR |

45dB |

43dB |

38.1dB |

34dB |

| 光学ポート |

C/CSマウント |

C/CSマウント |

C/CSマウント |

C/CSマウント |

価格はお問い合せください

価格はお問い合せください 価格はお問い合せください

価格はお問い合せください 価格はお問い合せください

価格はお問い合せください 価格はお問い合せください

価格はお問い合せください